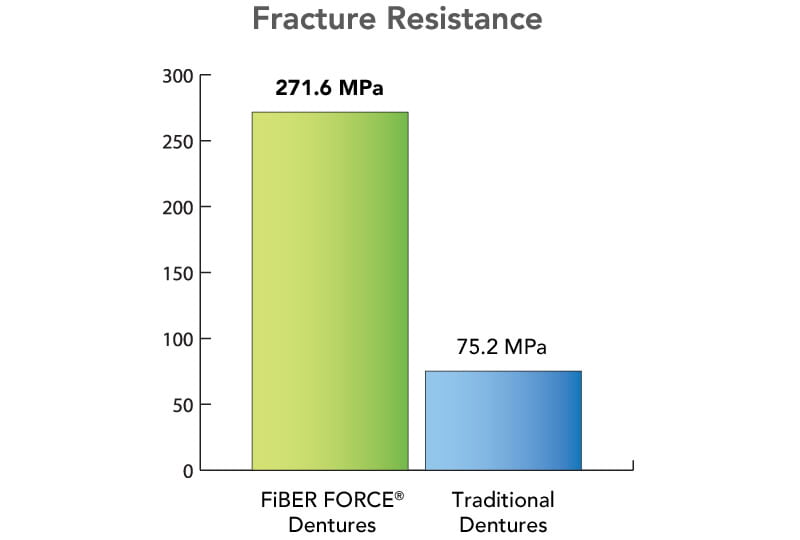

FiBER FORCE® is a versatile system that can be adapted to address reinforcement needs in many situations. In many ways the uses of FiBER FORCE® are only limited by your imagination and the case at hand. FiBER FORCE® chemically adheres to methacrylate acrylic and provides it with a threefold increase in strength.

> MSDS (Fiber Force Fiber)

> MSDS (Fiber Fore CST Resin)

> INSTRUCTIONS

> EZ VAC/Splintvac «troubleshooting»

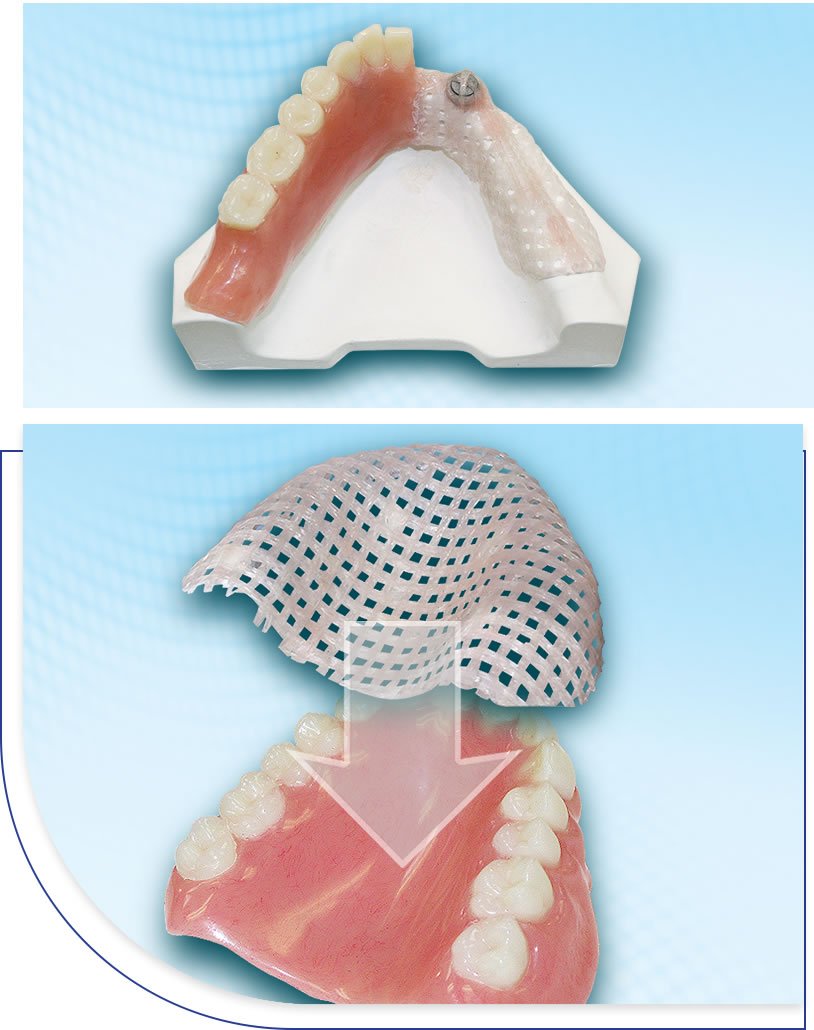

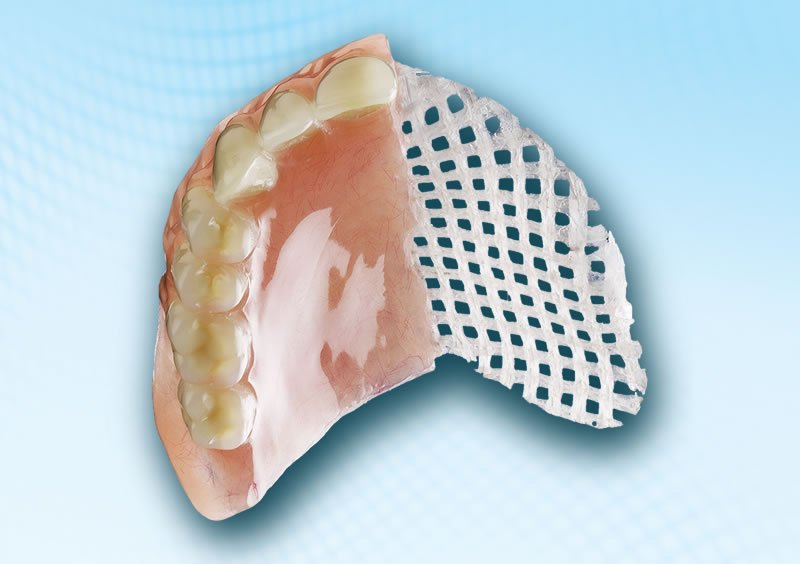

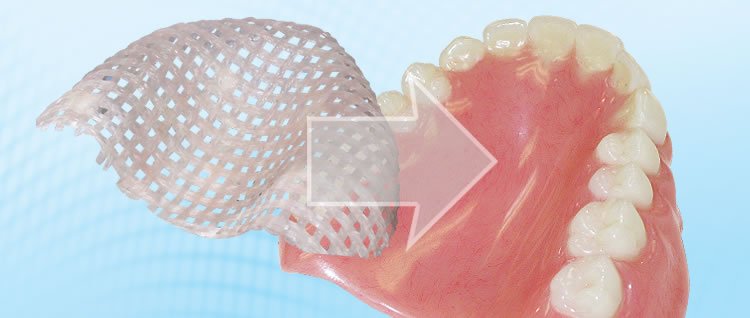

| The simple FiBER FORCE® technique is an ideal option to offer to all patients in need of full dentures. One package of mesh is enough material for up to three cases of full denture reinforcement with full palatal coverage. Two and a half cases is a reasonable average.

|

|

| FiBER FORCE® offers a an easy and inexpensive alternative that is strong, esthetic, comfortable, highly resistant to fatigue, and that offers bio-mechanics more similar to those of mandibular bone. A similar approach has been taken in aeronautics for all structures that must be lightweight and fatigue resistant.

|

|

| One study has confirmed that dentures repaired with fiber reinforcements are 58% stronger than the original dentures and 166% stronger than dentures repaired with acrylic alone.

|

|

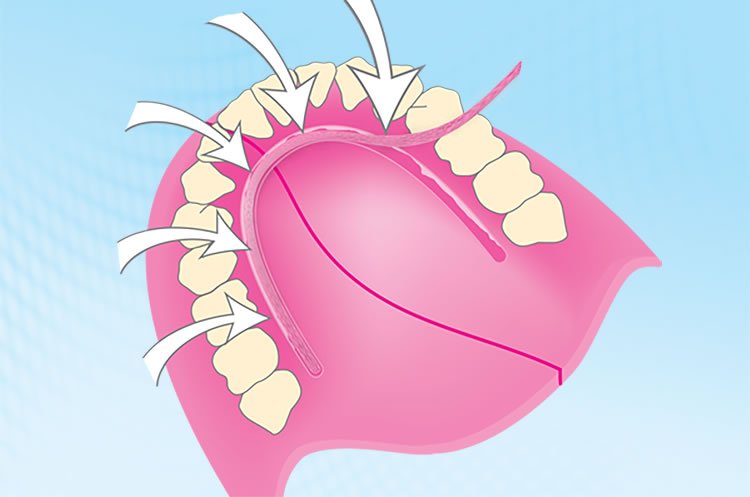

| Adding a tooth or teeth to an existing denture and having the alteration last is challenging, even if it is reinforced with a metallic wire. Reinforcing the tooth addition with FiBER FORCE® is easy, fast, and amazingly durable.

|

|

| Dentures with soft liners are more comfortable for denture wearers but not prescribed because the thin hard base makes them more prone to breakage. FiBER FORCE® mesh reinforcements significantly strengthen the hard acrylic base and make a denture with a soft liner an accessible reality.

|

|

| Long-term and long-span provisional bridges are prone to breakage, creating hassles, wasted time and money for all parties involved. Use FiBER FORCE® to bring temporary appliances to the end of their service life, easily and affordably.

|

|

| Stage One provisional dentures used when implants are placed and immediately loaded (as with the All on Four™ technique) are known to break routinely, causing frustration for all involved. These dentures can easily be reinforced, eliminating hassles and added costs.

|

|

| Acrylic “flippers” can break easily, creating unnecessary hassles for patients, dentists, and lab technicians. Fiber Force can easily be processed into the flippers making them strong and long-lasting.

|

|

The attraction of using E-glass material is due to its physical properties. As seen in the table below, E-glass has on one hand a very high tensile strength, yet on the other hand is a relatively elastic material. This is ideal for the type of stress forces seen intra-orally: repetitive forces that place a long-term strain on the appliance. Due to their inherent fatigue resistance FiBER FORCE® reinforcements allow the appliance to stand up to the stresses delivered.

The use of fiber reinforced composites (FRC) has evolved technically to the point that their use is widespread in a wide range of industries: aeronautical, automotive, and marine to name just a few. The physical properties and advantages of FRC are well understood and proven, and the use of these materials is common place. The primary benefits of FRC are their high fracture and fatigue resistance coupled with their light weight.

Material |

Tensile strength (MPa) |

Young’s elastic modulus (GPa) |

| E-Glass | 2000 | 80 |

| Steel | 531 | 200 |

| Titanium alloy | 900 | 105-120 |

| Stainless steel | 860 | 195 |

| Chrome – Cobalt | 750 | 225 |

| Chrome – Nickel | 570 | 170 |

| Enamel | 10 | 100 |

| Dentin | 100 | 20 |

| Cortical Bone | 170 | 20 |

| PMMA | 70 | 6 |

The overall level of reinforcement is further improved by the synergistic way the FiBER FORCE® and the acrylic/composite work together. With two materials bonded together chemically a “monoblock” is created – making the whole more resistant than the sum of its parts. This monoblock also shares and distributes loads in a more even way, as the FiBER FORCE® and the acrylic/resin have similar elastic properties. Thus the problems created when a very rigid material is simply sandwiched into the acrylic/composite are completely avoided.

Internal data from the manufacturers of FiBER FORCE® compared the fracture resistance of unreinforced full upper dentures to those reinforced with mesh. Test results showed a 300% increase in fracture resistance with mesh reinforcement.

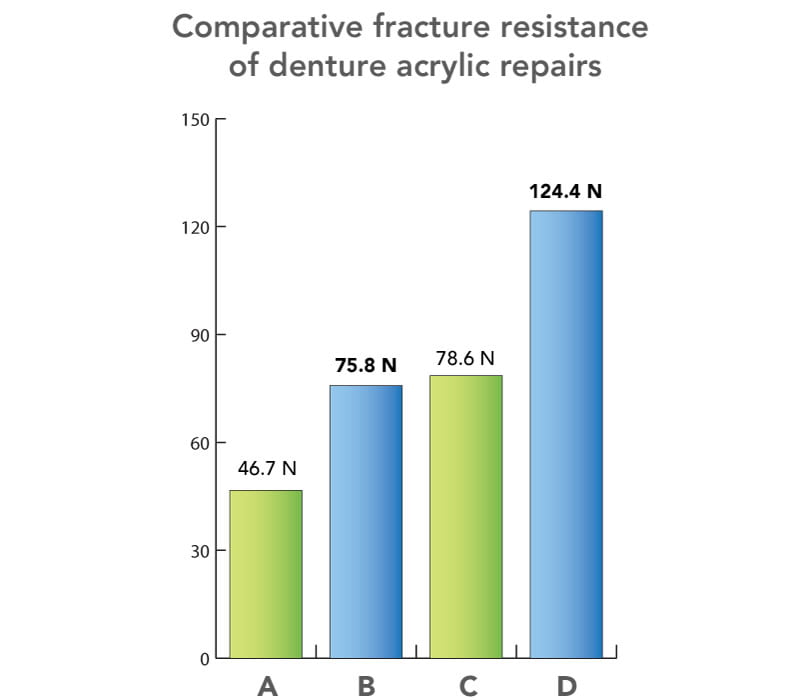

One study that looked at the effect of reinforcing acrylic with E-glass FRC showed that repaired acrylic is never as strong as it was originally. Using E-glass braided fibers returned the repaired acrylic to its original strength, while using UD fibers increased the resistance of the acrylic beyond its original strength.

|

A

|

Repaired denture acrylic without fiber reinforcement | 46.7 N |

|

B

|

Repaired denture acrylic with woven pre-impregnated e-glass fibers | 75.8 N |

|

C

|

Control group (new denture acrylic) | 78.6 N |

|

D

|

Repaired denture acrylic with UD pre-impregnated e-glass fibers | 124.4 N |

| FiBER FORCE mesh framework fabrication technique (8:52 min.) | FiBER FORCE repair techniques (8:12 min.) |

| Getting the most out of your EZ VAC vacuum former (4:17 min.) | |

Step by Step Instructions |

| > Production of methacrylate removable denture: INJECTION TECHNIQUE |

| > Production of methacrylate removable denture: PRESS TECHNIQUE |

| FiBER FORCE® Product Overview (4:09 min.) | FiBER FORCE® gets hammered! (7:51 min.) |

| Is FiBER FORCE® stronger than a cast metal mesh reinforcement? (3:08 min.) | FiBER FORCE® Reinforcement durability test phase two (0:50 min.) |

| EZ VAC – more than a one dimensional tool (2:43 min.) | |